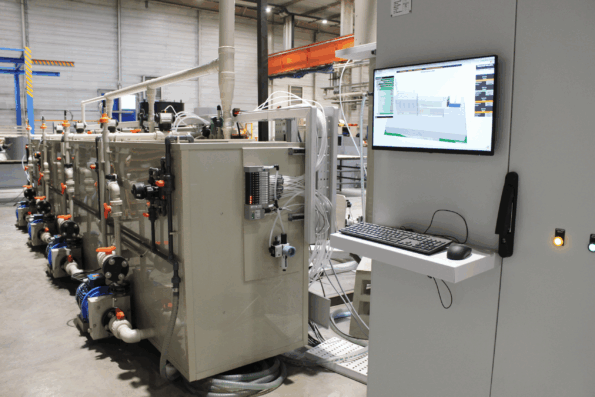

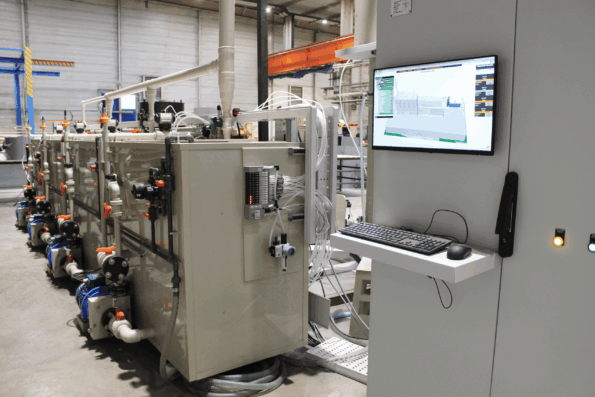

We designed and manufactured two automated stainless steel pickling machines for a European manufacturer specialised in boilers. Designed to meet the specific needs of the sector, they offer innovative solutions that can be fully integrated into the manufacturing process. These units are controlled by our supervision software which ensures complete control and monitoring of the installations, as well as production traceability.

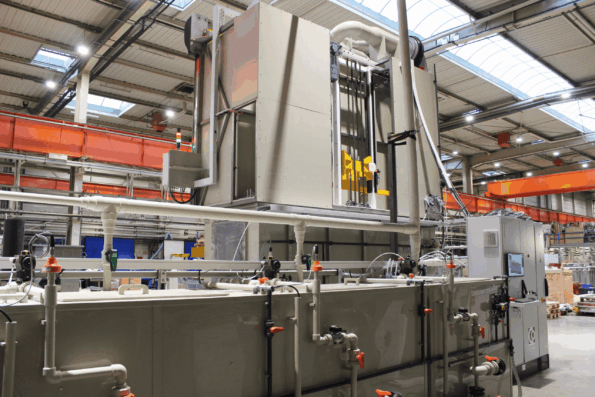

The first installation is a spraying cell dedicated to the complete pickling of boiler bottoms pre-equipped with various welded seams. The mobile sprinkler system ensures safe, effective and productive treatment.

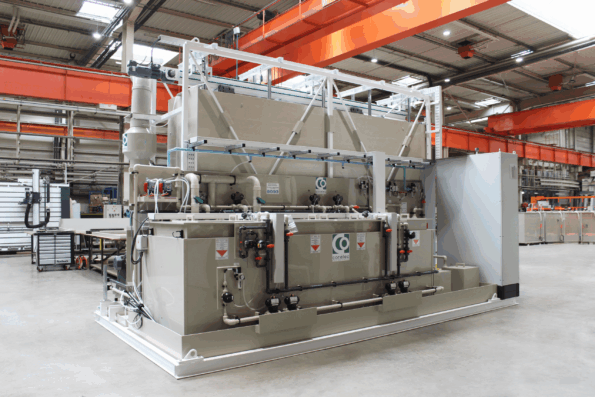

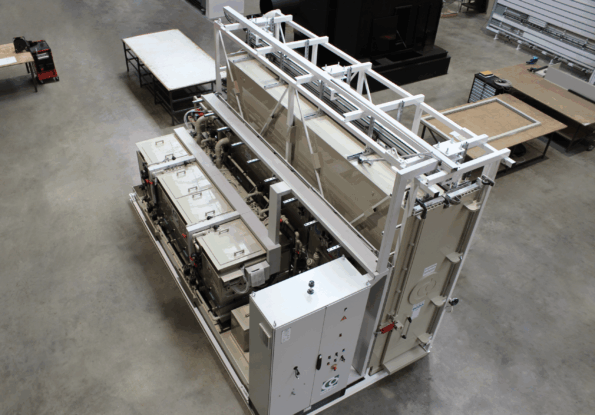

The second treatment unit is specially designed to treat the inside of stainless steel boilers at the end of the welding cycle.

This in-cab pickling machine uses innovative technologies to ensure complete and even pickling of the inner casing, as well as optimum rinsing at the end of the cycle, while saving as much water as possible.

The use of a rotating and telescopic nozzle per tank guarantees treatment of the entire inside of the boilers, whatever their size and internal accessories.

These two pickling units fully meet the productivity and quality requirements on which the performance and durability of stainless steel boilers depend.

With its wealth of experience, CORELEC Équipments can support you in your equipment projects with special machines for your routine or specific treatments.