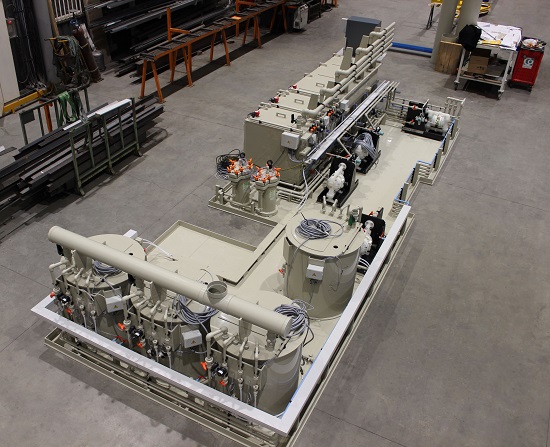

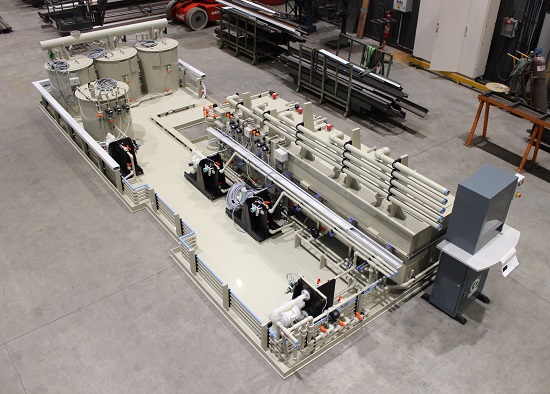

Thanks to our integrated manufacturing and assembly capabilities, we can carry out advanced shop test assembly prior to delivery of the plants, a guarantee of quality for our customers.

This example, among many others, enabled our customer to take delivery of his plant in a configuration close to the final version.

The equipment, piping and electrical wiring were entirely designed and modeled in 3D prior to manufacture to provide the routing and support integrated into the equipment. All this while considering the physical constraints of the site and using materials that can withstand the corrosive environment of surface treatment.

Our standard services save reassembly time on the final site and ensure that the equipment is pre-tested and designed for easy maintenance, without increasing its cost.

Our teams are ready to listen and respond to your surface treatment, water and air treatment, powder coating and painting projects, putting all our skills and resources at your disposal.